Flow simulation

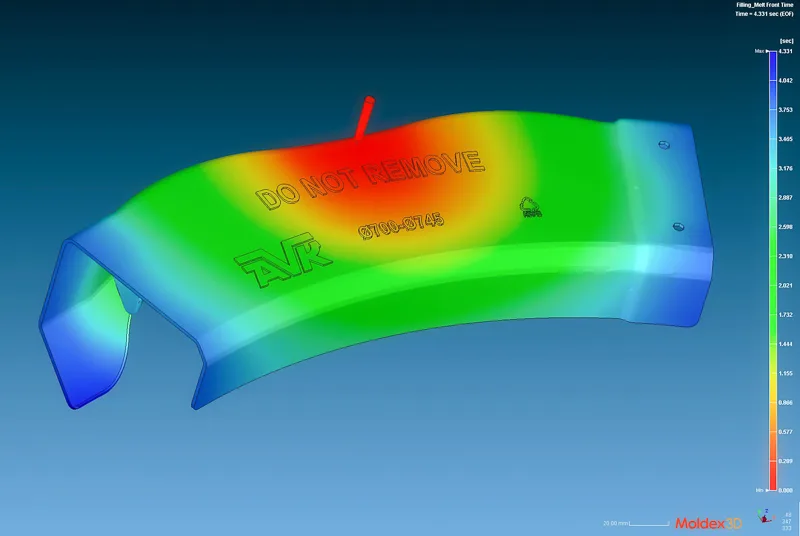

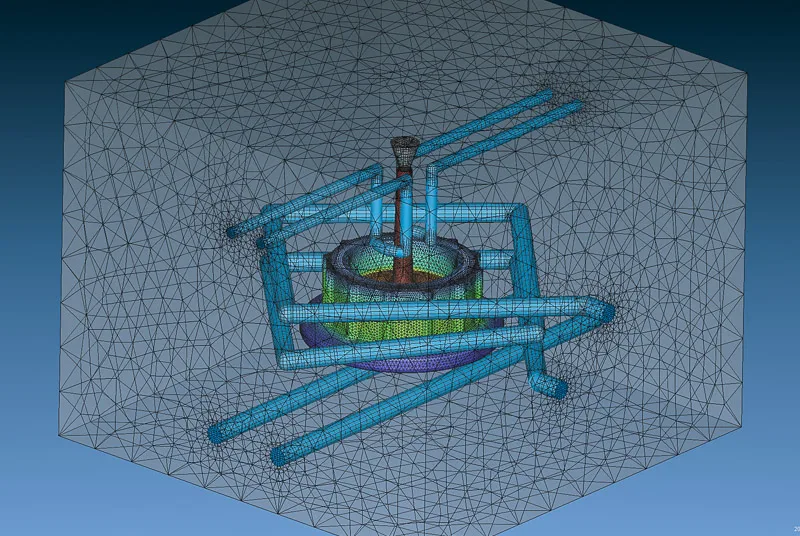

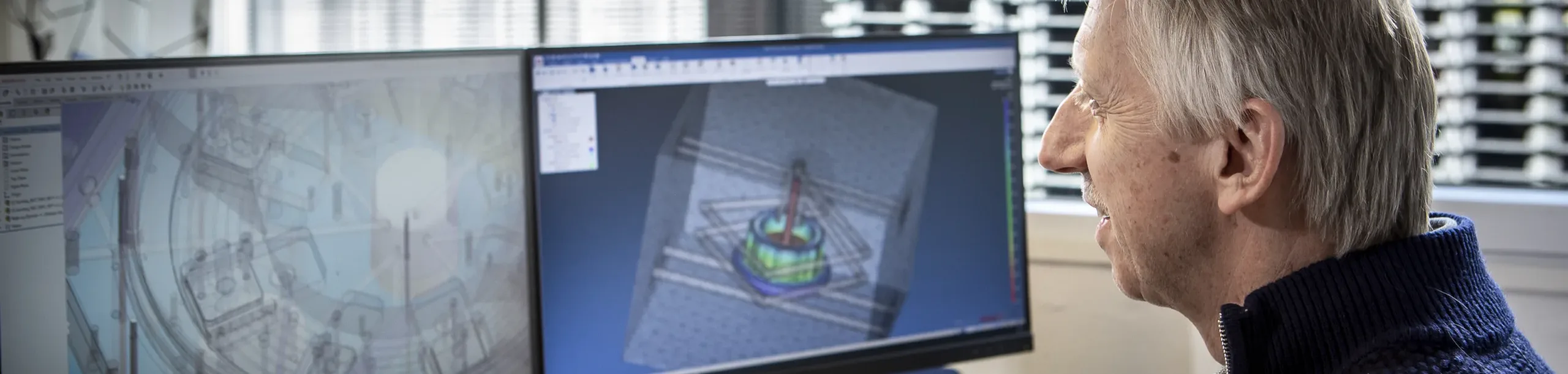

We perform flow simulations for optimizing product and tool design. For this purpose, we use the world leading simulation software Moldex3. Many of our customers utilize our offer to conduct high-tech simulations, in order to save time in the development phase, and costs in the production process.

By simulating the flow, we can predict how the actual material and the final product will behave during the injection moulding process. This will uncover potential issues with product or tool design. The benefit of Moldex3 flow simulation, is the possibility to uncover the issues at an early stage in the development process. Hereby, making it possible to achieve an optimal result.

Flow simulations using Moldex3 also reduces the number of prototypes necessary. Because we can detect construction errors at an early stage. That is why flow simulation contributes to reduced costs and saved time in the development stage.